|

<=Back

Features

of TM Pipe Fittings

a) Standards

TM fittings are produced in accordance with the following

national or international standards depending

on customers' requirements:

American

standards:

American

standards:

* ASME

B16.3

Malleable

Iron Threaded Fittings

* ASME

B16.39

Malleable

Iron Threaded Pipe Unions

* ASME

B16.14

Ferrous

Pipe Plugs, Bushings, and Locknuts with Pipe

Threads

* ANSI

/ ASME B1.20.1

PIPE THREADS, GENERAL PURPOSE (INCH)

British

standards:

British

standards:

*

BS143

& 1256

Threaded pipe fittings in malleable cast iron and

cast copper

alloy

*

BS

21

Pipe

threads for tubes and fittings where pressure-tight

joints are made on the threads

(metric

dimensions)

*

BS

EN 10242

Threaded pipe fittings in malleable

cast iron

ISO

standards:

ISO

standards:

* ISO

49

Malleable

cast Iron fittings threaded to ISO 7-1

* ISO

7/1

Pipe

threads where pressure- tight joints are

made

on the

threads-Part 1:

Dimensions, tolerances and designation

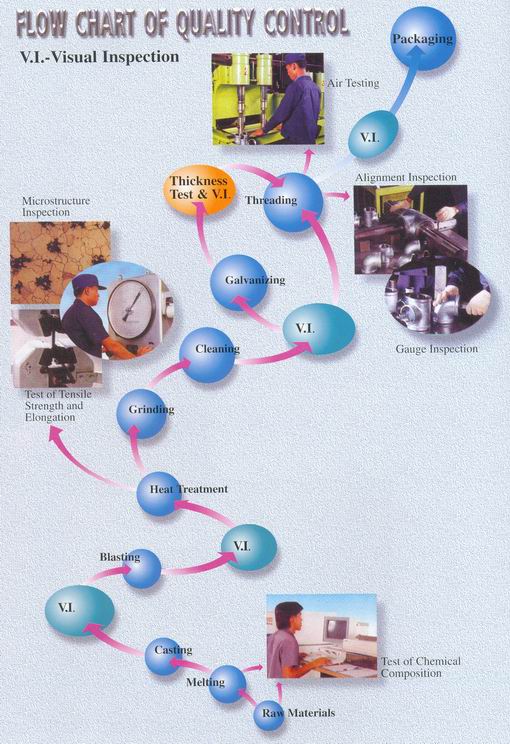

b) Material

TM fittings are manufactured

of black heart malleable

iron (the microstructure is shown on below picture). Our

iron

is melted and refined in electric induction furnaces, and annealed

with extreme care.

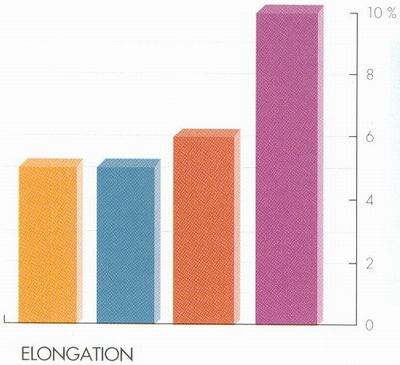

TM

malleable

iron has mechanical properties superior to those specified by

various

national / international standards for pipe fittings.

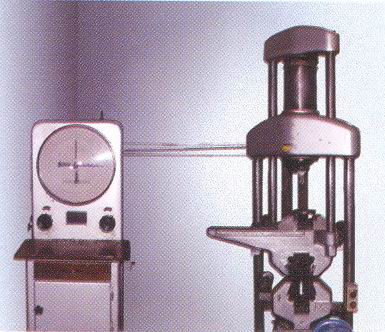

This

superiority is shown by the following two figures, in which

the Tensile Strength and Elongation of TM malleable iron are

compared with the specifications specified in some national

standards.

(Figures

of Comparison of Tensile Strength and Elongation)

C)

Coating

TM fittings are available

either galvanized or black. Galvanized fittings have an average

coating thickness of 86 micrometers or average coatings weight

of 610 g/m² or higher.

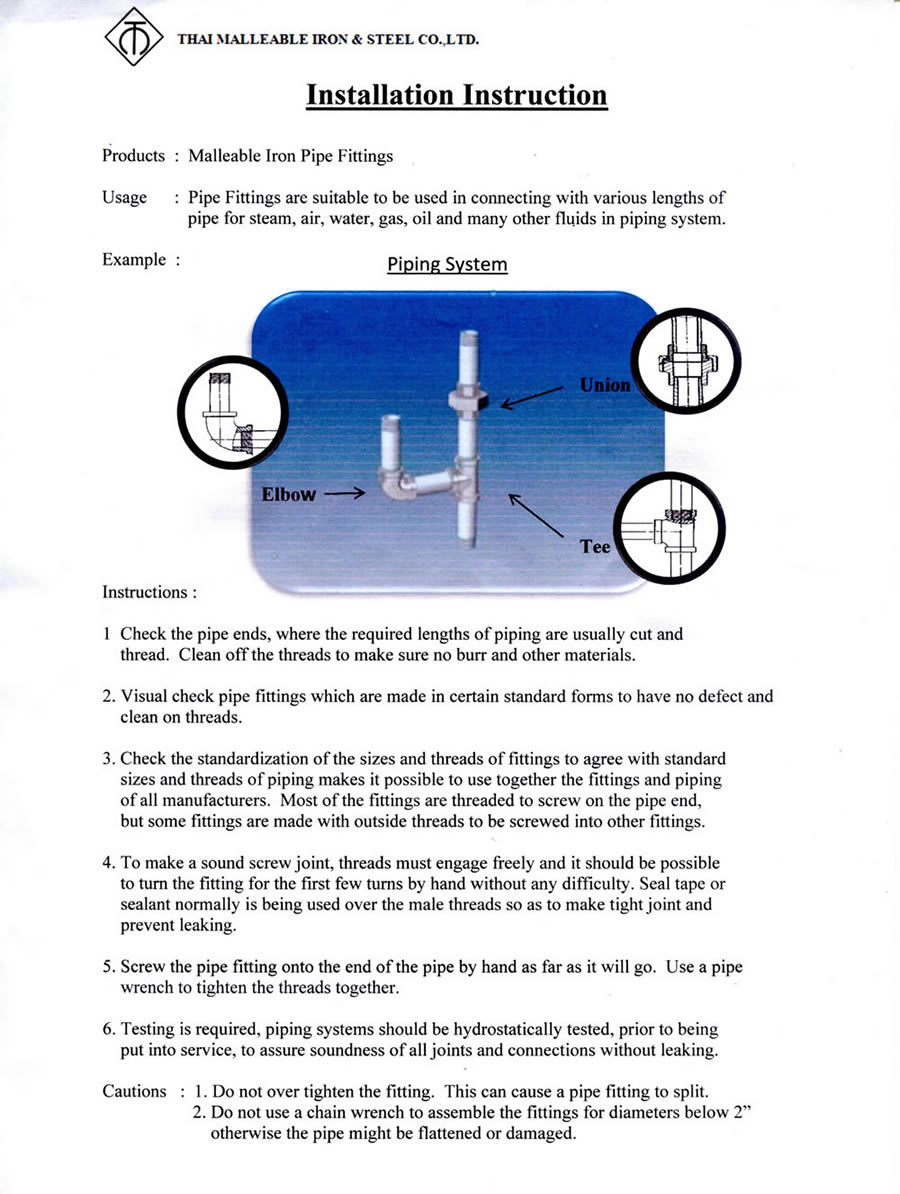

D) Applications

TM fittings are suitable to

be used either for steam,air,water,gas and oil pipes or for

many other fluids.

The recommended working pressure

under specified temperatures are rated as follows :

| Constituents

of Internal Fluid |

Maximum

Working Pressure |

Steam,Air,Gas

and Oil at 300 ° C |

10

kg/cm² |

Steam,Air,Gas

Oil and water at 200 ° C |

14

kg/cm² |

Water

Non-shock at 120 ° C |

20

kg/cm² |

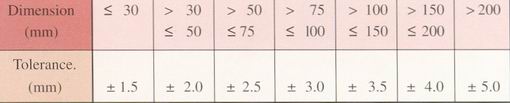

Distance

and Tolerances

The

important dimensions of TM pipe fittings are shown in the tables

on Dimensions

Specification

for BS

EN Standard,

Dimensions Specification

for

American Standard,

Quality

and Economy Our Ultimate Goals.Except

where stated as minimum dimensions, tolerances on face-to-face,

face-to-centre and centre-to-centre dimensions shall be in accordance

with below table.

End

Shapes and Threads

The end

shapes of TM

pipe fittings are illustrated on Dimensions

Specification

for BS

EN Standard and

Dimensions

Specification

for

American Standard. Our

Company manufactures

quality

pipe fittings with

different

end-shapes,

mainly banded, but also beaded or plain,

which are supplied upon our customers' preference.

TM

pipe fittings are tapped according to BS 21 or

ANSI / ASME B1.20.1 or ISO 7/1 standards, upon the customers'

specifications and requirements.Threads can also be machined

following German standard (DIN 2999) whenever requested

by our customers. All the threads are chamfered to assist assembling

and avoid "cross threading".

|